Electric Arc Bearing Damage

Arcing can be useful but in some instances unwanted arcing causes damage to industrial structures like bearings.

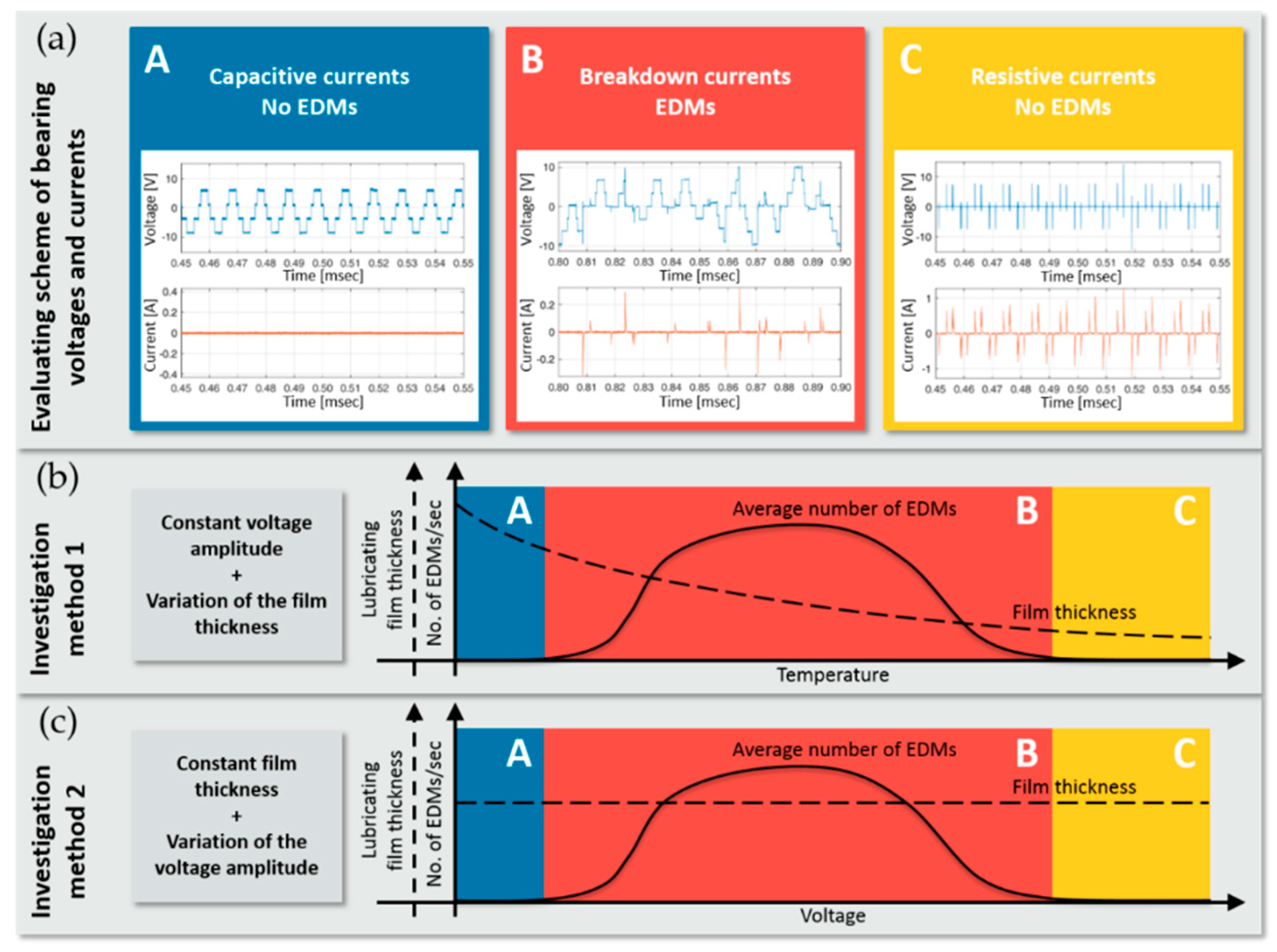

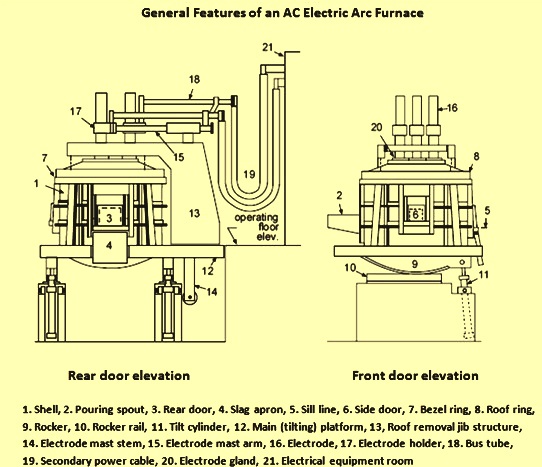

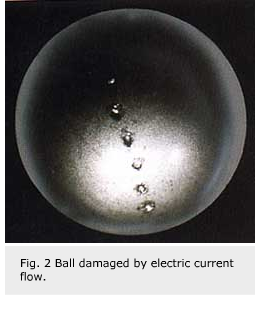

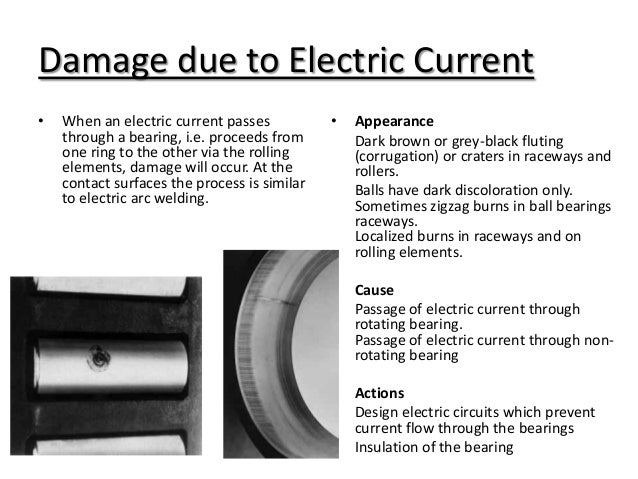

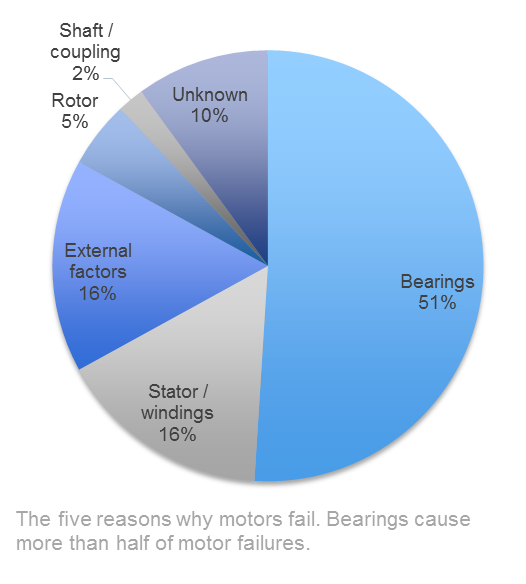

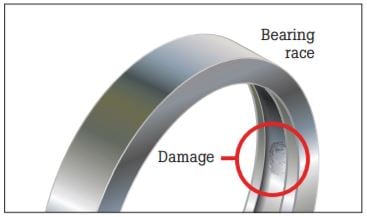

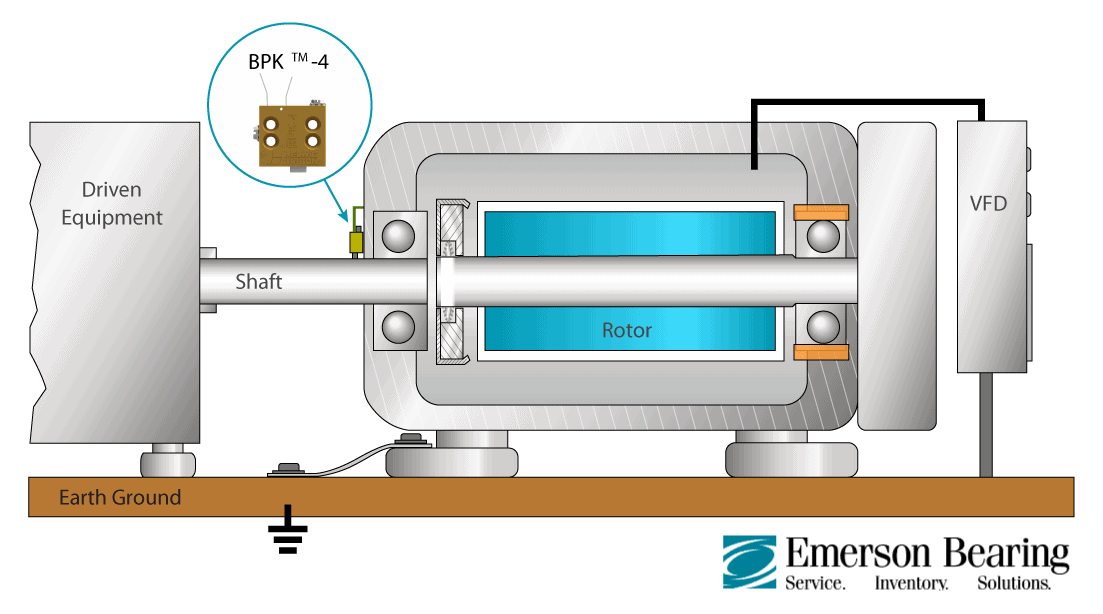

Electric arc bearing damage. When a stray current in a machine uses a bearing as its path to ground the resulting damage is referred to as electric arc bearing damage. This has distracted many from the general and w idespread incidence of this class of bearing damage. The damage usually appears on the surface of rings and rolling elements and is similar to that produced by electric arc welding. But when noise occurs the damage has usually become substantial enough that failure is imminent.

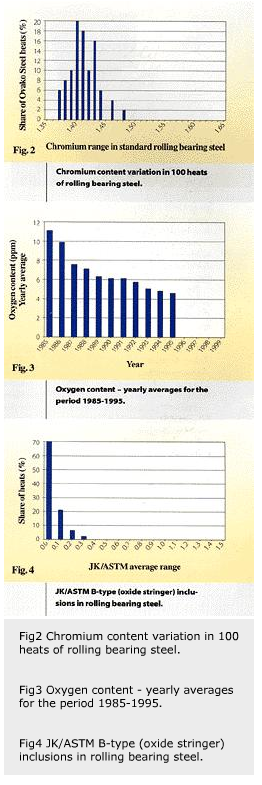

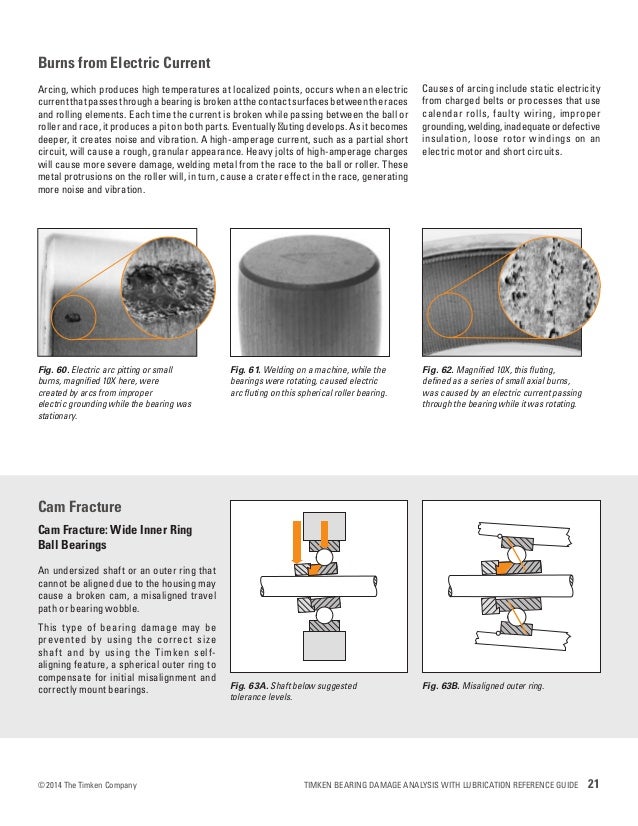

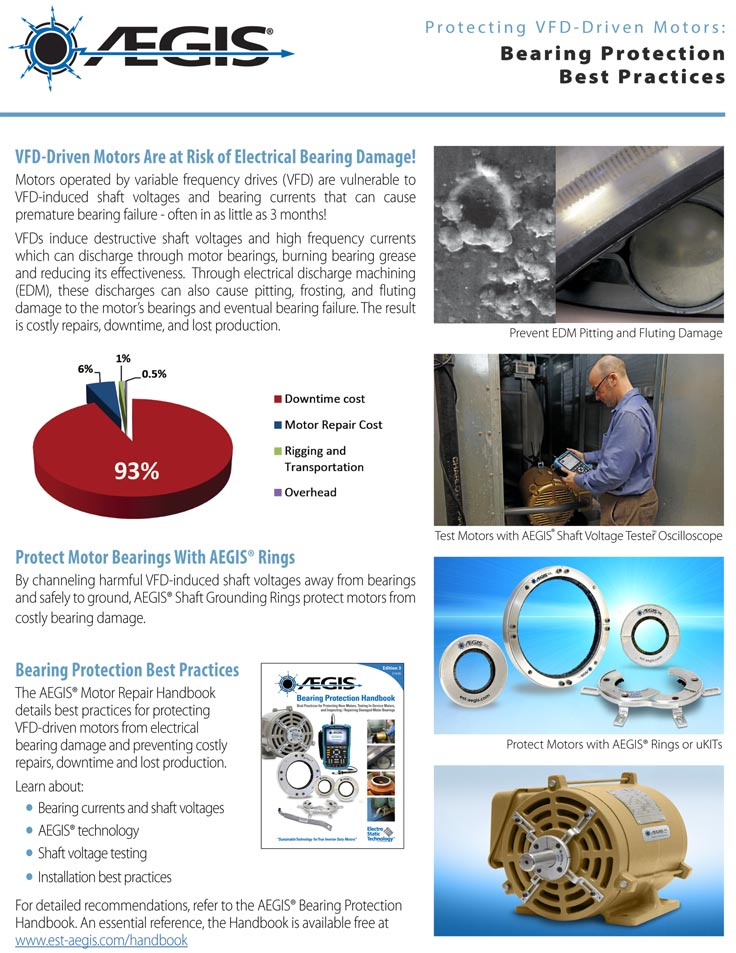

In extreme cases damage may occur very rapidly. In such a case the pitting may look blackened because of oil deposits. W hen bearing fluting or other evidence of electrical damage was clear the cause was frequently believed to be due to some local condition relating to power supply grounding or to a specific vendor or product. By some accounts electrical damage damage caused by electric discharge machining is the most common cause of failure for ac motors driven by vfds.

When it does the cause may be difficult to diagnose as pitting of the bearing surface is followed ultimately by wiping which may obscure the original pitting. Burns created by improper electric grounding while bearing is stationary. Ball bearings in electric motors support and locate the rotor keep the air gap small and consistent and transfer loads from the shaft to the motor frame. This electric discharge can occur at very low voltages and may cause severe pitting of the bearing or shaft surfaces or both.

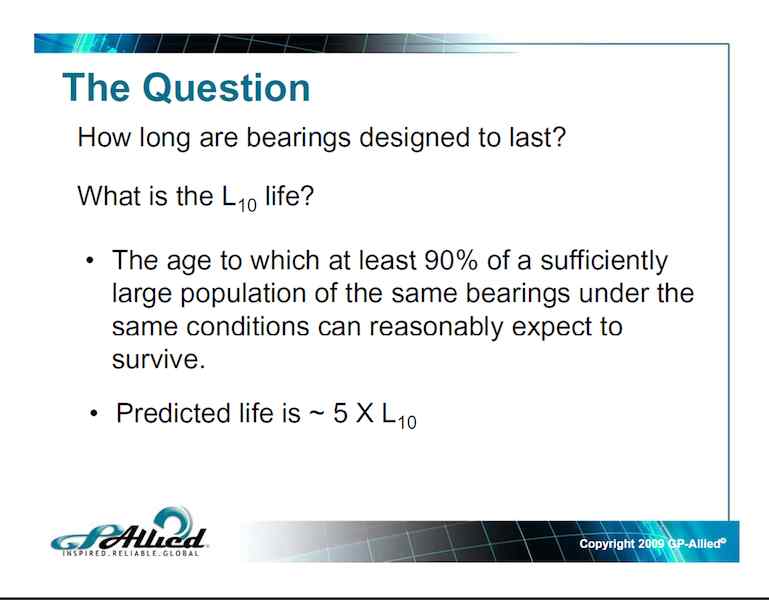

There s no definitive way to predict whether or when bearing currents will occur. The extent of damage to bearings depends upon the amount of energy and its duration. Electric arc fluting fluting caused by electric current roller with electric arc burns adhesive wear on bearing inner ring roller flats adhesive and skidding wear on raceway surface roller end with adhesive wear cage pocket wear from excessive roller movement wear at small ends of cage pocket and on roller bridges scalloping marks in the cup. For instance electrical pitting may be present in the linings of bearings where there is insignificant arcing.

Either visible regular patterns flutting or. Improper fit damage electric current damage fluting. Once electric arc bearing damage has begun excessive vibrations increased heat increased noise levels and the reduced effectiveness of the lubricant will combine to shorten a bearing s service life.

.jpg)