Drawn Arc Stud Welding Ceramic Ferrule

Our welding technology explained in detail.

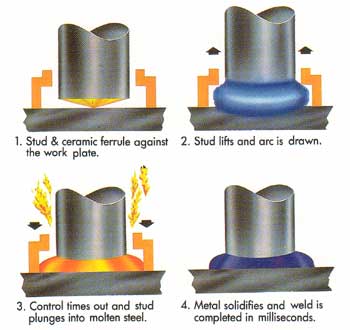

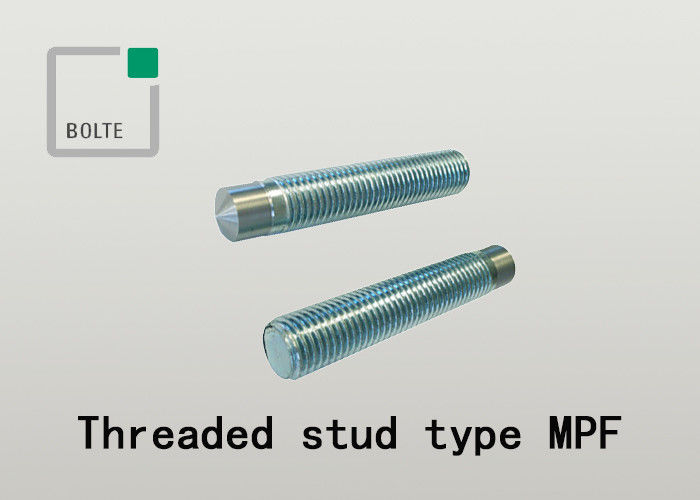

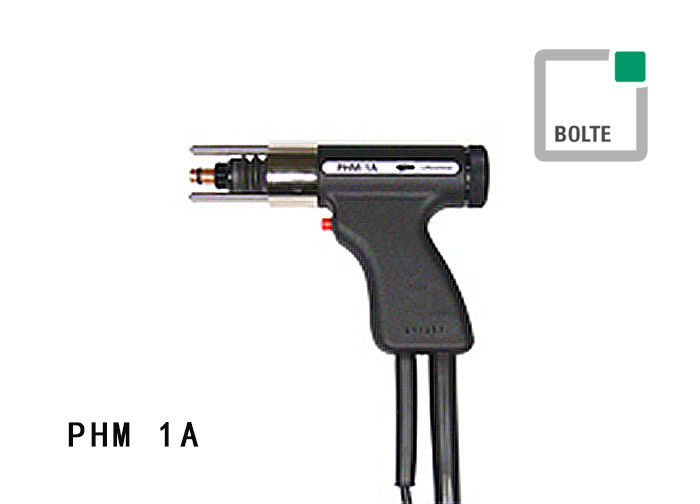

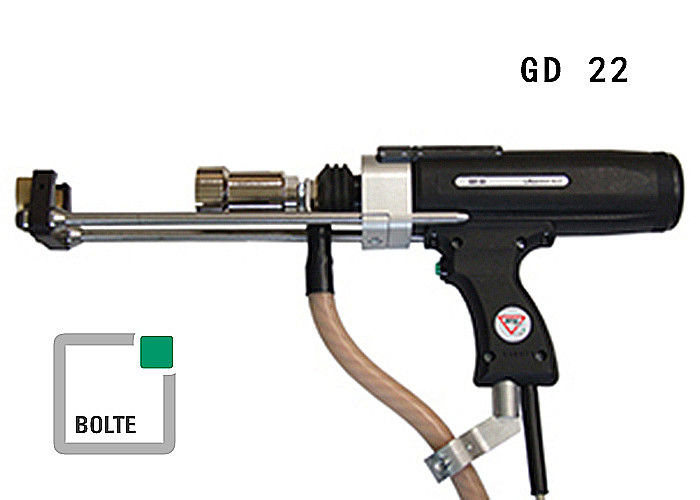

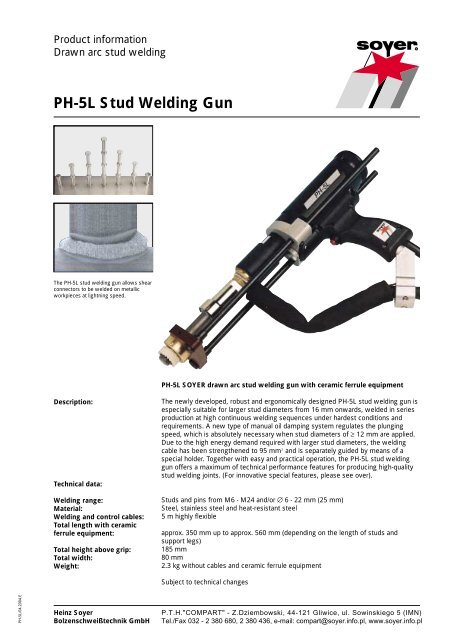

Drawn arc stud welding ceramic ferrule. The stud will be inserted into the chuck of the stud welding gun and positioned onto the workpiece possibly by adding a ceramic ferrule. This ceramic ferrule contains the tip of the welding stud and more effectively distributes heat and shielding gas around the weld point. Used for multiple purposes in stud welding. Ceramic ferrules are essential part of the standard shear connectors shear studs drawn arc stud welding process.

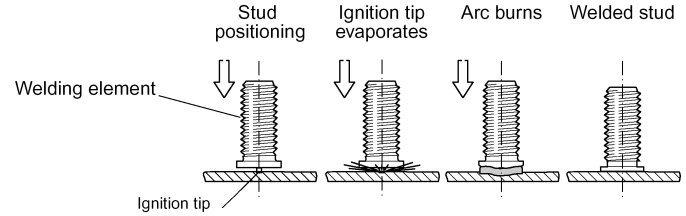

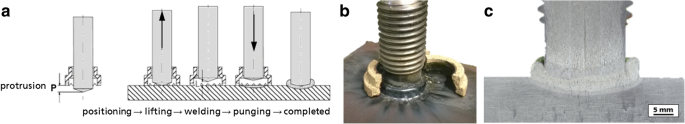

Drawn arc stud welding. In the process the shear connector will insert into the center hole of the ceramic ferrule the ceramic ferrule will be pressed on the welding surface by ceramic ferrule holder by the force of spring device inside the welding gun. By means of a lifting mechanism the stud will be lifted and at first an auxiliary arc pilot arc of a low current will be drawn. In general the positive pole of the power source is connected to the workpiece.

Drawn arc stud welding with ceramic ferrule. Firstly the drawn arc machine is set up for the appropriate stud diameter. Third the ferrule forms the molten metal into the fillet. The best aluminum studs have a built in ignition tip that burns away before the weld is performed.

Finally the fillet vents allow weld gases to escape. Weld studs are a permanent solution to fastening metal to metal. The stud is usually joined to a flat plate by using the stud as one of the electrodes the polarity used in stud welding depends on the type of metal being used. Another key difference in aluminum welding is the stud design for drawn arc stud welding processes.

Second it minimizes the atmosphere that the flux must purge. Without ceramic ferrules the drawn arc process wouldn t be effective and welds wouldn t be as strong. Welding aluminium for example would usually require direct current electrode positive dcep. Initiating the welding process.

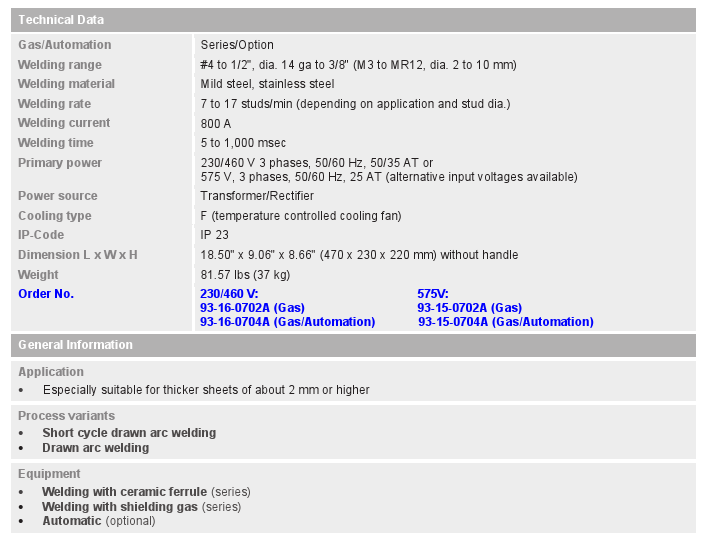

Ferrules are disposable items. Drawn arc stud welding joins a stud and another piece of metal together by heating both parts with an arc. First the ferrule helps to shield the arc from the operator. The process drawn arc stud welding is used for studs of an approximate diameter of 3 to 25 mm welding current up to 3 000 a and welding times up to 3 000 ms.

Ceramic ferrules are required for drawn arc stud welding because the process is a longer weld time than other welds the welding studs are typically thicker in diameter and the weld will be required to hold greater weights than other welding formats. Bolte gmbh home. To understand why it s important to know how drawn arc stud welding works.